01254 492329

Info@Buildersalliance.co.uk

08.00 TO 18.00

Monday to Saturday

13 Railway Road, Darwen

Lancashire BB3 2RG

Builders in Haslingden

Builders in Haslingden

Timber Frame Extension: Planning, costs & Finishes

Thinking about a timber frame extension? This guide reveals all – from finance and planning permission through to cost implications and the build methods.

A timber frame extension is an excellent way to add much-needed extra space to your house and offers many benefits. With a timber frame extension, the weathertight step can be completed in days rather than weeks, which involves less time spent on site, decreased levels of disruption and less dependency on right weather conditions.

Once made, a timber frame extension can also offer great levels of thermal performance and airtightness, making it fitting for projects with sustainability at their core. If you want to go to a timber frame extension, you will need to think how the frame is manufactured, the best selection of exterior finish, whether you require planning permission and importantly, what is possible within your budget.

If you desire to use timber frame for a self-build project, review our beginner’s guide to the timber frame.

Is a Timber Frame Extension More affordable than Other Systems?

Ordinarily, yes. The cost of a timber frame extension is believed as being less than a traditionally-built extension primarily because there are fewer labour hours required.

The timescale needed to build it is also more predictable with it being less reliant on right weather conditions, primarily if the works are being carried out in the winter months.

Funding a Timber Frame Extension

If you intend to take out or increase a current mortgage to boost pay for the extension, you should evermore check with the lender what external finish is satisfactory to them, and some are very conservative on what external finish they will accept which may limit your choice of lenders.

Also, with any home renovation or extension project, remember it should add more value to your home than it costs to begin the work.

Do I Require Planning Permission for a Timber Frame Extension?

Not fundamentally. If your aimed extension meets specified criteria in terms of position and size, then you may be ready to extend under Permitted Development Rights (PD). If you want to develop something outside of the scope of PD, then you will wish to planning permission.

Always double-check with your local authority before starting work, mainly if your property is listed or located in a conservation area or Area of Excellent Natural Beauty.

Is a Timber Frame Extension Built On-Site?

The vast majority of extensions built using timber frame are ‘stick build’ – this is where the timber frame panels are built up on-site by the joiner as opposed to being manufactured in a factory.

A structural engineer would design the timber frame and present a specification of the size/grade of timbers to be used for the frame/lintels/cripple studs and so on, collectively with a nailing schedule.

The joiner would take control of all the timbers required, and as they are loose, they can effortlessly be maltreated through restricted access areas to wherever the panels are to be made up.

The joiner would then make up the timber frame panels on-site following the architectural engineer’s specifications, and because the current structure would be opened up/exposed at this point, it enables him to take accurate dimensions and make the panels to suit.

If your preferred design features large expanses of glazing, then a steel or glulam opening frame/goal post arrangement may be needed (a structural engineer would recommend on this aspect). This can be manufactured off-site, delivered in segments and bolted together on site.

Be conscious that if any part of the extension is below complete ground level, then timber frame construction would not be fit for that element of the build.

Can I Utilize a Factory-Manufactured Timber Frame?

You may discover that manufacturers are hesitant to quote for extension projects as they demand a lot more technical input when related to a new build. Very accurate site dimensions have to be given for an extension to make sure the likes of floor levels, eaves and roofs line through with the current house.

It is sometimes nigh impossible to get accurate manufacturing dimensions until details of the existing home can be opened up/exposed to learn precisely how it was initially constructed. That can create considerable delays as most manufacturers will have a lead-in time of at least 6-8 weeks from having all the knowledge they require before the delivery date.

Businesses may also be put off providing a quote if the site way is very restrictive. And, with the regular single-storey extension of say 3.6 x 4.8m only needing a part load, it makes the transportation costs uneconomic when matched to ‘stick build’.

Which Exterior Finish Works Best on a Timber Frame Extension?

The timber frame extension can be completed externally in a variety of materials, including:

- Facing brick

- Rendered brickwork/blockwork

- Native stone

- Reconstituted stone

- Brick slips

- Timber

- Fibre cement cladding

- Metal cladding

- Render board system

But, if being built on a boundary, then the external finish has to be non-combustible and provide a minimum of one hour’s fire resistance to satisfy Building Regulations.

Top Tips for Extending with Timber Frame

- Choose a designer with experience in designing timber frame extensions

- Get three detailed quotes and go over them with your designer to ensure you are comparing on a like for like basis

- Always have a contingency budget of around 10% to deal with any unforeseen circumstances

- Don’t forget to budget for external works including paving, decking and landscaping

Factoring in a Movement Gap

Wherever any extension (irrespective of the building method used) is connected to the existing building, it is essential to ensure a movement gap is formed to accommodate shrinkage, thermal and moisture flux.

The extension will most probably be a different construction to that of the existing building and as such, will open/contract at a different rate to the current building, hence the necessity for a movement joint.

Movement joints are typically made by using a stainless steel channel tie system which gives lateral restraint but allows for both horizontal and vertical movement, the gap created between the two structures is filled with a resilient sealant (various colours are available) to make it weathertight.

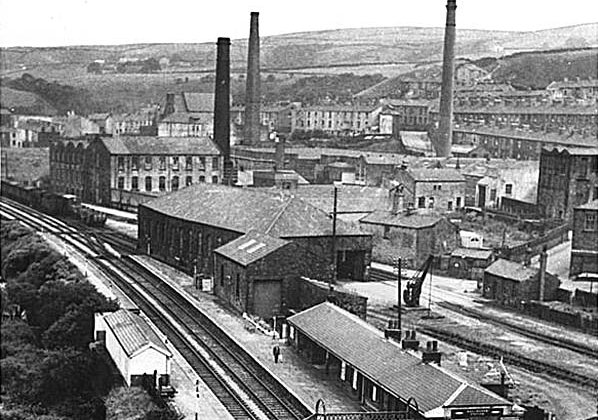

Fun Facts about Haslingden

Workhouse - Haslingden had a town workhouse placed on Spring Lane dating from 1749.

Part of what is presently Haslingden, along with that of the adjoining towns of Rawtenstall and beyond that Bacup was part of the Forest of Blackburnshire, that part meaning the Forest of Rossendale. The Forest was a hunting park through the late 13th and 14th centuries; 'Forest' connected to it being parkland rather than being densely wooded, as the Forest declined much sooner, during the Neolithic period.